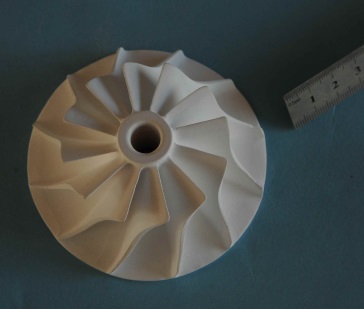

Industrial custom made production from ceramic

Our company has mastered the production technology of complex-shaped ceramic parts. We manufacture parts from corundum, cordierite and zirconium ceramics, electrical porcelain. Production of carbide-silicon ceramics has been started.

Using our existing additive technologies (prototyping), reverse engineering technologies (3D scanning) and technologies developed by us for manufacturing “lightweight” equipment, we can quickly and efficiently produce products according to the customer’s specifications, without excluding orders for individual samples.

Physical and mechanical properties of the ceramic materials used

| Chemical composition | Module, GPa | Strength, MPa | Hardness, GPa | Thermal conductivity, W/m*K | KTR, 10-6 K-1 | Density, g / cm3 |

| Al2O3 | 400 | 400 | 12-15 | 25 | 8 | 4.0 |

| ZrO2(Y) | 240 | 640 | 8-10 | 2 | 10 | 5.9 |

| ZrO2(Y)+20% Al2O3 | 280 | 1200 | 10-12 | 6 | 9 | 5.5 |

Pressing

ZrO2 (60-90%) with the addition of a stabilizer and white clay as a binder. The composition of the ceramics will change, and depends on the customer’s requirements

Main characteristics (depend on the conditions of synthesis and additives):

| Refractoriness | 1500 – 2100оС |

| Temperature of the beginning of deformation under load 2 kgf / cm2 | 1500 – 1900оС |

| Loss tangent | 0,03 – 0,0002 |

| The tensile strength in bending | 800 -1000 МПа |

| Strength | 6 -10 МПа*м1/2 |

| Hardness |

12 – 13 ГПа |

Examples of ceramic products

The class of technical ceramics combines a large number of ceramic materials that differ both in chemical composition and purpose. At the same time, there are features common to all technical ceramics that fundamentally distinguish them from traditional types of ceramics:

Using mainly, and for some ceramics exclusively artificially synthesized raw materials (powders).

Application of new technologies, primarily powder metallurgy technologies.

It should be noted that the properties of technical ceramics, especially mechanical, depend crucially on the technology of obtaining raw materials, compacting and sintering products. Therefore, materials of the same chemical composition, but obtained in different ways, can have qualitatively different levels of physical, chemical and mechanical characteristics and a wide variety of applications.

Silicates and aluminosilicates form the basis of a very large number of technical ceramic materials. Most of these ceramic materials, as the predominant phase, contain double or triple crystalline substances-silicates or aluminosilicates formed in the MDO-A12O3-SiO2 system. There are four such connections in this system:

ZA12O3ּ| 2SiO2-mullite

Mgoּ / SiO2-clinoenstatite

2mgoּ| SiO2-forsterite

Mgoּ| 2A12O3ּ| 5SiO2-cordierite.

In accordance with the name of the minerals called and ceramics – mullite, mullito-corundum, clinoenstatite (steatite), forsterite and cordierite.

Electrical ceramics are divided into 4 major categories – magnetic, dielectric, semiconductor and conductor, including superconducting. All of them are characterized by the ionic structure of crystal lattices. Let’s first consider a variety of dielectric ceramics-porcelain. The main components of porcelain are plastic clays and kaolins, which are water-based aluminosilicates. The chemical formula of kaolin is Al2O3.2SiO2.H2O. The composition of porcelain also includes quartz materials (SiO2), feldspar (microcline K2O. Al2O3. 6SiO2), alumina (Al2O3), calcite (CaCO3), etc.

Fired porcelain consists of crystals of 3al2o3.2SiO2 mullite and SiO2 quartz, the gaps between which are filled with a glassy material formed mainly as a result of melting of feldspar.

Electrical porcelain contains approximately 70% SiO2 and 25% Al2O3. The rest is accounted for by K2O, Na2O, Fe2O3, etc.

Radiopharphor has higher dielectric properties, the glassy phase of which is ennobled by the introduction of heavy VAO oxide into it.

Further enhancement of radioparty is ultrafilter. It contains an increased amount of alumina Al2O3 and VAO. Ultrafilter is used as the dielectric high frequency up to microwave.

Similar in composition and properties to porcelain is steatite ceramics. It mainly consists of MD silicates and is made on the basis of talc minerals 3mdo.4SiO2.H2O. The recipe of steatite ceramics and the conditions of the sintering process are chosen so as to exclude polymorphic transformations of magnesium silicate. In addition to magnesium silicate, the formulation includes mineralizers ZrO2, ZnO, Vaso3 and Mdso3, which bind SiO2 silica, which is released during the decomposition of talc when it is heated.

A distinctive feature of the ceramic materials discussed above is a very rapid deterioration of the dielectric properties with increasing temperature: increasing tg, falling .

All these materials have a positive coefficient of thermal conductivity, lying in the range of (3-9) .10-6K-1.

Chemical-laboratory tableware is very popular when conducting chemical-analytical experiments and various types of auxiliary work in both chemical-analytical and clinical-diagnostic laboratories.

Porcelain is a material obtained from a mixture of several substances: kaolin (white clay), quartz, feldspar and some other aluminosilicates. Almost always, porcelain products are covered with a very thin layer of special glaze during the manufacturing process — it increases the abrasive strength, and in addition, resistance to aggressive acids and alkalis. The most important advantage of porcelain, when compared with glass, can be called heat resistance and mechanical strength. Superhard varieties of porcelain that are used to make laboratory glassware without glaze can withstand heating up to 1300 degrees, while porcelain coated with this glaze softens as early as 1200 degrees.

All laboratory tableware made of porcelain is highly resistant to hot acids.

A Buchner funnel or a funnel with a septum, are used in laboratories for carrying out the processes of filtering of chemical solutions under reduced pressure (vacuum) through filter paper. All surfaces of such a funnel, excluding only the upper edge, are covered with a thin layer of glaze. They are manufactured strictly according to the requirements of GOST 9147-80.

Mugs, cups, glasses made of porcelain have different capacities. The inner and outer parts of them, excluding the bottom outside, are covered with a strong glaze.

Boats that are used for burning organic substances, as well as for determining the level of carbon content in the composition of steels are made of heat-resistant porcelain. Boats differ in shape and are not covered with glaze. Boats are manufactured according to GOST 9147-80.

Quite often in laboratories, porcelain spoons are used. For grinding substances — mortar business. A pestle is attached to such a porcelain mortar. The high strength of porcelain makes it possible to make crucibles and spatulas from it as well.