Metal is a choice of material used in this modern era for any types of furniture, daily utensils even for houses’ or other buildings’ construction. A good polishing can make those metal-based things look stand out, luxurious and shiny.

WHAT IS METAL?

Metal is a solid material that is typically hard, shiny, malleable, fusible, and ductile, with good electrical and thermal conductivity. According to an article on Wikipedia, metal is a material that, when freshly prepared, polished, or fractured, shows a lustrous appearance, and conducts electricity and heat relatively well. Metals are typically malleable (they can be hammered into thin sheets) or ductile (can be drawn into wires). A metal may be a chemical element such as iron or an alloy such as stainless steel. In physics, a metal is generally regarded as any substance capable of conducting electricity at a temperature of absolute zero.

THE TECHNOLOGY USED IN PRODUCING METAL PRODUCTS

The first basic step in metal production always involves some form of mining. Mining is the extraction process of metal materials from the earth. The process continues to the next step which are purification and then reduction.

Metal purification, also known as metal refining, means vaporizing or melting the metal. The process of vaporizing the metal and then allowing it to solidify outside of the impurities is called distillation. Otherwise, melting the metal, and allowing it to run out of the solid impurities is named liquation.

Then, the process of reduction. Reduction is a chemical reaction that is the opposite of oxidation. Metals can be reduced in a variety of different ways.

The final stage of metal production

In the final stages of metal production, the finished product is formed into some shapes that can be used in other industries to make final products. Thus, steel or other metal materials can be purchased in the form of flat sheets, rings, wire rope and thread, slabs, cylinders, and other shapes.

1. Pressing

Metal Pressing (also known as stamping) which is the process of placing flat sheet metal in either blank or coil form into a stamping press where a tool forms the metal into a net shape. Stamping includes a variety of sheet-metal forming manufacturing processes, such as punching using a machine press or stamping press, blanking, embossing, bending, flanging, and coining (Kalpakjian, 2001).

How does it work?

Simply, the process is done by either pressing the metal with a pressing tool or using a stamping die. Stampings or pressings is created by inserting flat sheet metal into a specialist machine often referred to as a stamping press. Pressings and stampings can be used to become a part of many important products in modern day society

A stamping die is a special as well as a precision tool that cuts and forms sheet metal into a desired shape or profile. The die’s cutting and forming sections typically are made from special types of harden-able steel called tool steel

Stamping Dies Manufacturer

Such stamping products are commonly produced for home appliance manufacturers, automotive companies, the lighting industry, telecommunications services, military and defense, aerospace industries, medical equipment manufacturers, and electronics companies.

2. Moulding

Metal Moulding in which the metal powders and a thermoplastic binder are mixed. The binder is only an intermediate processing aid and must be removed from the products after injection molding.

Metal Moulding is a manufacturer of custom metal fabricated products, primarily for the Marine market, including hinges, arm rests, brackets, panels and trim, as well as plastic products including boxes, inlay tables, steps, and related components.

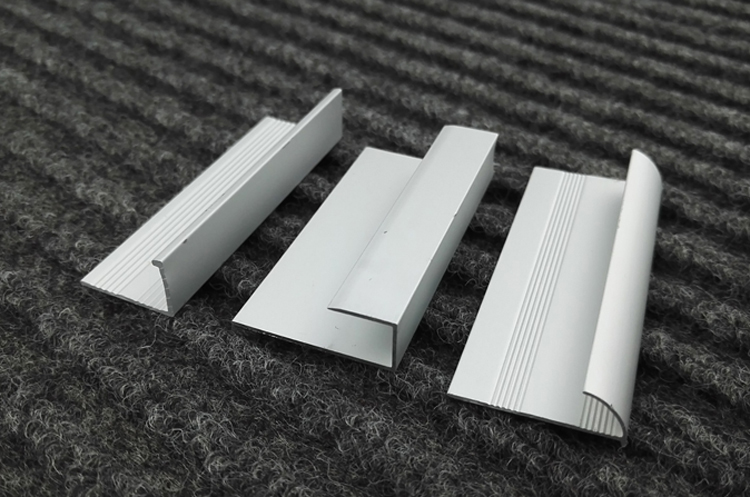

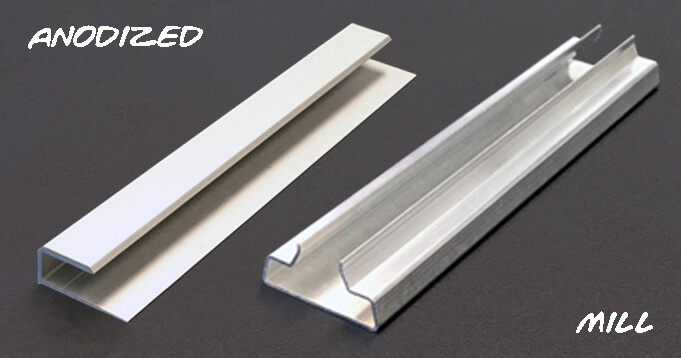

Profiles and Shape

A Metal Moulding (Molding) is generally made from thinner materials than Profiles and Special Shapes. Mouldings are also made from Decorative Metal in many instances. Profiles can be from thinner metals but are usually considered more structural in nature. Special Shapes is a catch-all phrase that encompasses both Metal Profiles and Mouldings. Structural Shapes are common but can also be thinner and decorative.

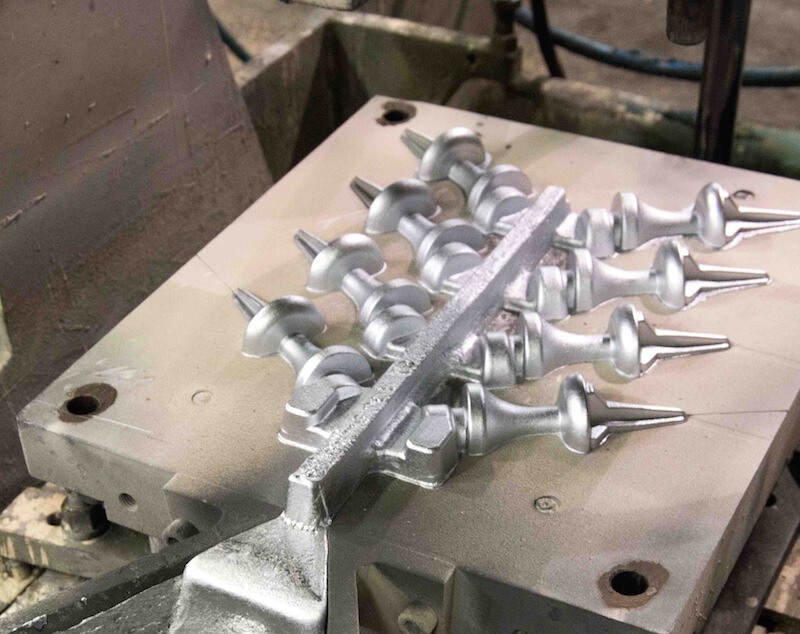

Moulding is nothing but the mould preparation activities for receiving molten metal. It is known as casting. Metal casting is defined as the process in which molten metal is poured into a mould that contains a hollow cavity of a desired geometrical shape and allowed to cool down to form a solidified part. Molding is a multistep process that will form a cast around the pattern using molding sand. In casting, a mold is contained in a frame called a flask.

3. Metal Injection Moulding (MIM)

This process allows high volume, complex parts to be shaped in a single step. After molding, the part undergoes conditioning operations to remove the binder and to dense the powders. Finished products are small components used in many industries and applications.

Customized Precision Metal Injection Molding

Metal injection molding (MIM) merges two established technologies, plastic injection molding and powdered metallurgy. This technology is aiming at creating high performing small precision metal components to almost any level of complexity and at virtually any volume.

Metal Injection Moulding

As a green technology

As it is an advanced metal forming technique that uses injection molding equipment for manufacturing both simple and complex metal parts to tight tolerances, metal injection moulding can be used across a wide range of components. Though larger parts are possible to make, but the best applications are typically small and weigh less than 100 grams. But the materials can be brazed to a variety of components for a complete assembly set. One of the advantages of using metal injection moulding technology, which is also considered as a green technology, is less material waste. It as a result of producing near net shape components.

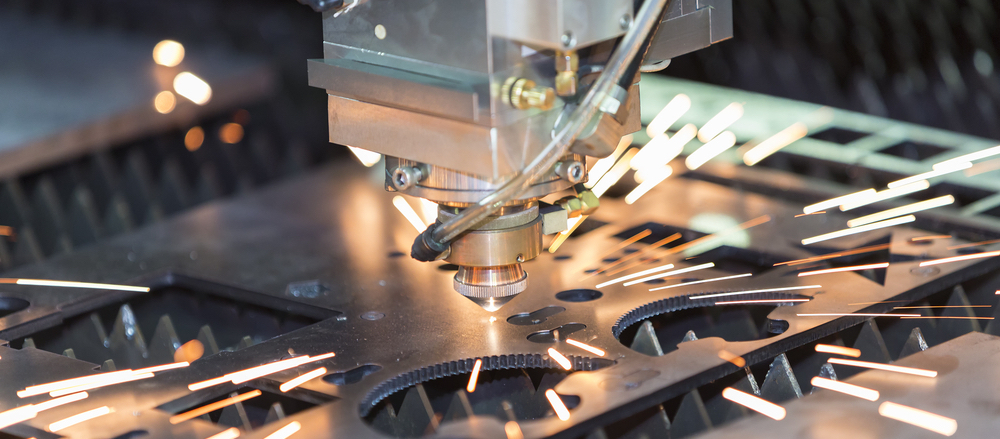

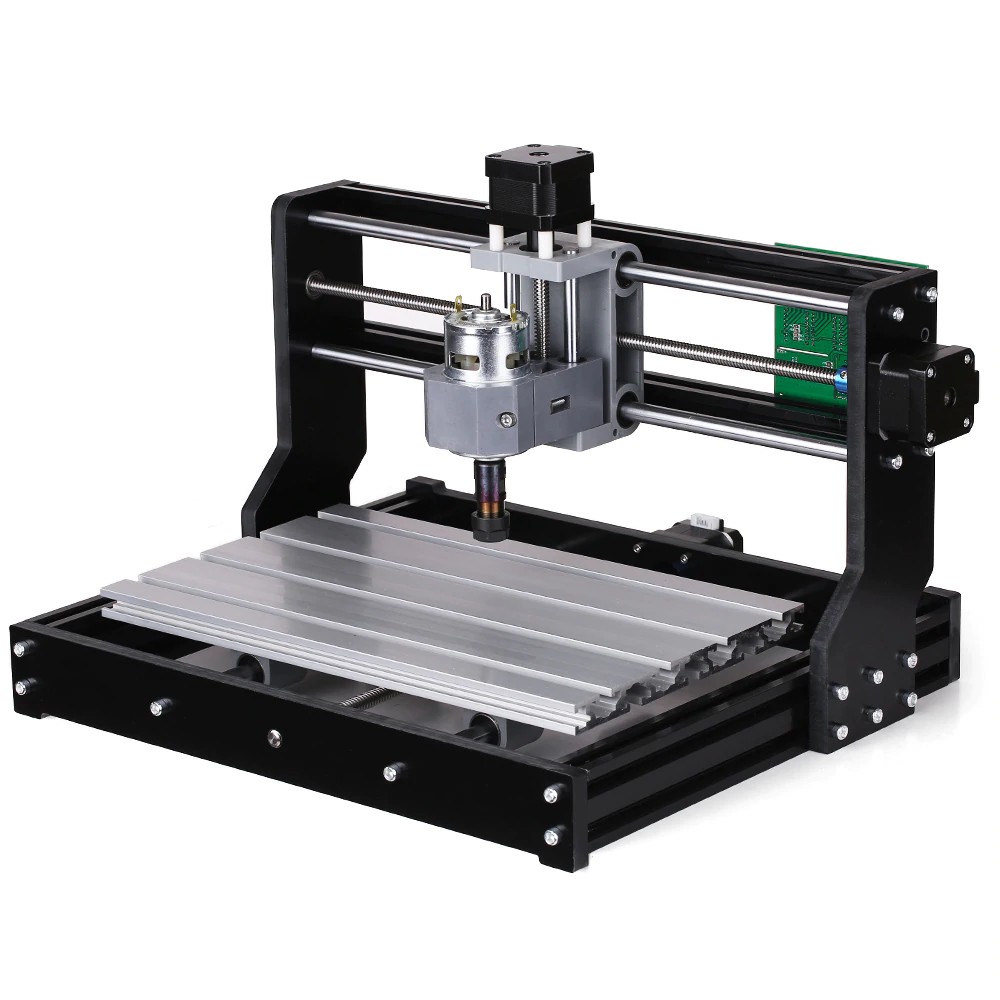

4. Laser Cutting

Laser Cutting to precisely cut sheet metal, even the very difficult one. There is no cutting edge which can become contaminated by the material or contaminate the material because the laser system has a small heat-affected zone. It is a technology that uses a laser to slice materials.

Laser Metal Cutting Machine is able to cut almost any type of metals as stainless steel, carbon steel, copper and others. This method works by directing the output of a high-power laser most commonly through optics.

There are several techniques that can be performed with a laser too, as follows:

- Marking which is a process that can also be completed with a laser. It also involves the melting of a surface layer of a material to leave a mark behind.

- Engraving, it is very similar to marking, with the difference being that the aim here is to create a deep, engraved mark. It is often used for applications such as creating barcodes or a more detail pattern.

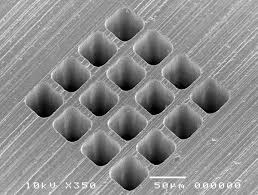

- Drilling is another common process that can be used with a fiber laser. Drilling involves the creation of popped holes or dents in a material. Laser drilling is the process of creating thru-holes, referred to as “popped” holes or “percussion drilled” holes, by repeatedly pulsing focused laser energy on a material. The diameter of these holes can be as small as 0.002” (~50 μm). If larger holes are required, the laser is moved around the circumference of the “popped” hole until the desired diameter is created.

With this huge range of types and techniques, it means it has use for a vast range of applications across industries such as aerospace, automotive, electronics, semiconductors and medical, as well as in schools and for hobbyists with things such as art to create interesting and complex shapes.

Visit our other pages about Metal Materials in this link and Metal Custom Production in this link.

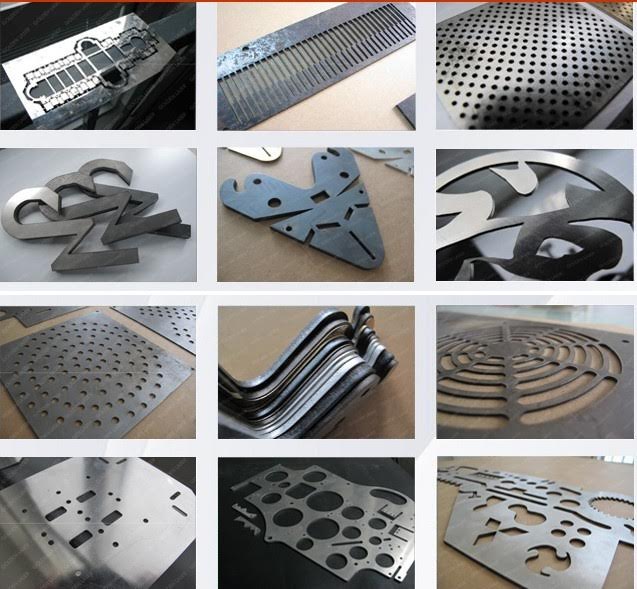

Metal Custom Products

Metal is a choice of material used in this modern era for any types of furniture, daily utensils even for houses’ or other buildings’ construction. A good polishing can make those metal-based things look stand out, luxurious and shiny.

How to Produce a Metal Product

There are few steps to produce a customized metal products. Here are some ways:

- Metal Stamping (pressing) which is the process of placing flat sheet metal in either blank or coil form into a stamping press where a tool and die surface forms the metal into a net shape. Stamping includes a variety of sheet-metal forming manufacturing processes, such as punching using a machine press or stamping press, blanking, embossing, bending, flanging, and coining (Kalpakjian, 2001)

- Molding is the mixing process of the metal powders and a thermoplastic binder. The binder is only an intermediate processing aid and must be removed from the products after injection molding.

- Metal Injection Moulding (MIM), this process allows high volume, complex parts to be shaped in a single step. After molding, the part undergoes conditioning operations to remove the binder and to dense the powders. Finished products are small components used in many industries and applications.

- Laser Cutting to precisely cut sheet metal, even the very difficult one. There is no cutting edge which can become contaminated by the material or contaminate the material because the laser system has a small heat-affected zone.

Please click here to see the further explanation of the metal production technology.

Metal has been widely used since prehistory era. According to an article on Wikipedia, things from metal were began used over 9000 years ago, when people found out how to get copper from its ore. They then learnt how to make a harder alloy, bronze, by adding tin to the copper. About 3000 years ago, they discovered iron. By adding small amounts of carbon to iron, they found that they could make a particularly useful alloy which is steel. Nowadays, people’s live almost cannot be separated with the use of metal-material things around.

There are some basic steps in order to get raw metal from the earth, such as mining, metal purification and also reduction. There are also vary technologies used in creating metal products as pressing or also known as stamping, moulding or in some sort also called as metal casting, metal injection moulding process and laser cutting in which including marking, engraving and drilling.

Click here for further explanation about the steps and technologies in creating metal products.

Types of Metal

There are 2 types of metal, the pure one and alloy.

A pure metal is any metal that has not been joined with any other metal or synthetic material which means it has not been alloyed with other metallic elements. Depending on the degree of purity, the pure metals could be classified as high-purity metals (99.90–99.99 percent pure), super purity or chemically pure metals (99.99–99.999 percent pure) and ultra pure metals (more than 99.999 percent pure). Pure metal are the substance that contains atoms of only one type of metallic element. it is made into an alloy to improve the properties of a pure metal. However, the majority of pure metals are too soft and malleable to be used. Hence so, there is an alloy as a metal made by combining two or more metallic elements, especially to give greater strength or resistance to corrosion.

There are various types of metal that we usually find in our daily life such as iron , carbon steel , aluminum , stainless steel, alloy and copper .Iron and steel products are widely applied in many applications, from office furnishings to outdoor settings, even for medical tools and automotive.

1. Iron and Cast Iron

Iron is a metal that has a whitish gray color. The metal is produced by smelting hematite ore in a blast furnace. It is used in buildings and in engineering, can also be used to make steel alloys. Iron makes up about 5% of the Earth’s crust and a large part of the Earth’s core. It is a pure metal, existing as a single element whereas cast iron is alloyed iron which is iron alloyed with elements such as carbon or silicon. Iron metal undergoes oxidation when exposed to air and moisture to form rust while cast iron is not oxidized by moisture.

It is resistant to damage by oxidation

An article on Wikipedia reads that cast iron tends to be brittle, except for malleable cast iron. It is resistant to damage by oxidation. Cast irons have become an engineering material with a wide range of applications and are used in pipes, machines and automotive industry parts, such as cylinder heads, cylinder blocks and gearbox cases. It is also used for home appliance such as cookware as for dutch oven or pan, stove and kitchen appliance finish to make the kitchen has a matte finish look and reducing some minor dents.

This kind of metal is also primarily for outdoor use. The hardness, heaviness and general rugged structure make it ideal for outdoor finishing and setting. It is an unbeatable material for outdoor use.

2. Aluminium

Aluminum is a light property as well as corrosion resistant metal. It is one of the most world-widely used type of metals. It almost can be anything, from cooking ware to automotive tools, also used in air traffic power cables, airplanes, ships, cars, as well as beverage cans. Aluminum is a metal that has a silvery white color. The metal is derived from the ore, bauxite, by electrolysis. Light, durable and functional: these are the qualities that make aluminium one of the key engineering materials of our time.

Aluminium is called the green metal because it is a very environmentally friendly metal. Recycling this material saves 95% of the energy required to produce aluminium from raw materials. This means it plays a key role in human ecology. Here are other advantages of aluminum used:

1. Good conductor of heat and electricity

Aluminum is the best electric and heat conducting metal after copper. However, because copper is more expensive, the use of items that require electricity or heat tends to use aluminum. We can see that the average cookware or electricity uses aluminum as the base material

2. It has a color that does not change quickly

Aluminum has a bright color and, although over a long period of time, the color does not fade or rust quickly. Aluminum actually reacts very quickly with oxygen in the air and forms aluminum oxide. It is precisely this aluminum oxide that will protect the inner layer of aluminum from the continuing reaction. So that it seems as if aluminum is resistant to chemical outside influences.

3. Does not React With Chemicals In Food

This is the secret why many foods come with aluminum foil packaging. And many cooking utensils are made of aluminum. Because this metal will not react with chemicals in food, we will feel safe when cooking anything with aluminum cookware.

3. Copper

Copper is one of the oldest used metal material. It has been used since 10.000 years ago. Copper is recyclable without any loss of quality, both from raw state and from manufactured products. It is a type of metal that is malleable, and has a reddish color that is used to make its alloys form of brass or bronze. Even at its melting point, copper keeps its pink luster color. Most copper is used in electrical equipment such as wiring, electric cables, hot water tanks, and motor.

Copper is used widely in any sectors such as:

Electricity Sector

The benefits of copper in the electricity sector are arguably very vital. Apart from silver, copper is the most effective conductor of electricity. This is due to its resistance to corrosion, ductility, flexibility, and its ability to conduct strong electric currents, making it ideal for making electrical cables

Construction Sector

Copper pipe is now the standard material for drinking water pipes and heating systems in most developed countries. Here copper is used because of its bacteriostatic properties, or in other words the ability of copper to inhibit the growth of bacteria and viruses in water

Transportation Sector

The benefits of copper in the transportation sector can be seen in the core components of aircraft, trains, cars and ships all depending on the electrical and thermal properties of copper. In automobiles, copper, brass, and oil coolers have been industry standards since the 1970s.

Other Sectors

The list of copper uses will always be growing dynamically. As for cooking utensils, clock, coin, music instruments, also for art as can be found in Liberty Statue.

4. Alloy

An alloy is a combination of metal or metals combined with one or more other elements. Red gold is an example of an alloy, as it is a combination between gold and copper. Sterling silver is also an example of alloy, it combined silver with copper. One of the most beautiful alloy products is white gold, which is actually a mixture between gold and silver.

More than 90% of the metal used is in alloy form. Alloys are used because their chemical and physical properties are superior to applications than pure elemental components. Typical enhancements include corrosion resistance, increased wear, special electrical or magnetic properties, and heat resistance. Other times, alloys are used because they retain the key properties of metal components, but are less expensive.

Here are various types of alloys that mostly used recently:

Steel, the name given to alloys of iron with carbon, usually with other elements, such as nickel and cobalt. Other elements add desired qualities to the steel, such as hardness or tensile strength.

Stainless Steel, another iron alloy, which usually contains chromium, nickel and other elements to resist rust or corrosion.

18k gold, this is actually only 75% gold. Other elements usually include copper, nickel, or zinc. This alloy retains the color and luster of pure gold, but is tougher and stronger, making it more suitable for jewelry.

Brass, which is a mixture of copper with zinc and sometimes other elements, is hard and durable, making it perfect for plumbing fittings and machine parts.

In general, the use of metal are for various purposes. It can be for industrial or personal used. It is also can turn to be metal custom products. Where the customers can customize the metal products for their industries.

Click here to see our offers.

Metal Production by Material

There are various types of metal such as iron , carbon steel , aluminum , stainless steel, alloy and copper .Iron and steel products are widely applied in many applications, from office furnishings to outdoor settings.

Cast Iron is primarily for outdoor use. The hardness, heaviness and general rugged structure make it ideal for outdoor finishing and setting.

Aluminum is a light and corrosion resistant metal. It is one of the most world-widely used type of metals. It almost can be anything, from cooking ware to automotive tools.

An alloy is a combination of metal or metals combined with one or more other elements. Red gold is an example of an alloy, as it is a combination between gold and copper. Sterling silver is also an example of alloy, it combined silver with copper. One of the most beautiful alloy products is white gold, which is actually a mixture between gold and silver.

Copper is one of the oldest metal material. It has been used since 10.000 years ago. Copper is recyclable without any loss of quality, both from raw state and from manufactured products. Even at its melting point, copper keeps its pink luster color. Most electrical equipments are using copper such as wiring and motors

Stainless Steel

In this modern and instant era, we need to carefully choose our daily cooking utensils. Stainless steel is the best material for kitchen utensils. By using stainless steel kitchen utensils, it can produce good, high quality food and is safe to use. In terms of maintenance, stainless is also easy to clean because it has a flat, non-porous texture and is very strong. In addition to being luxurious and shiny, stainless steel cookware is often used because of its anti-rust. The question is, is the stainless steel cookware safe for food? Yes, of course. Stainless steel is safe for food as long as it is used and cared for properly. Before using it for the first time, wash stainless steel cookware with warm water and dish soap. Scratches / minor scratches on the surface of stainless steel is reasonable because of usage.

Stainless Steel Food Ware Benefits

Here are the reasons why use a stainless steel-based food ware to keep our food

1. Easy to clean

Because the texture is flat and smooth, stainless steel is one of the easiest materials to clean.

2. Is an insulator

Stainless steel kitchen utensil is a thermal insulator. It keeps the food heat longer.

3. The best quality material

Because stainless has a high level of strength and is resistant to oxidation and corrosion. Stainless material is ideal for kitchen equipment in restaurants, hotels and so on. And stainless is also as an attractive finishing and does not require expensive maintenance costs.

4. Very strong

Stainless steel is the strongest material. Because it is made of metal or aluminum so it is strong and not easily broken or dented due to collisions or when falling.

5. Does not contain pores

Stainless is made of metal so that the surface is tight and does not contain pores. Because it does not contain pores, stainless kitchen utensils are not easy to leak or crack.

6. Durable

The most durable and durable kitchen utensils are stainless. Because the ingredients are chromium and nickel.

7. Prevents oxidation

Stainless steel has 16 to 24% chromium and 35 nickel. The chromium material can prevent oxidation in kitchen utensils and nickel serves to prevent corrosion so that kitchen equipment can be resistant to rust and moisture.

8. Low maintenance costs

Stainless steel kitchen equipment has low maintenance costs. Because stainless is easy to clean and does not cause corrosion or rust. And stainless also has a slippery texture so it is safe and easy to clean.

9. Multifunction

Kitchen utensils made of stainless steel are more multifunctional than other materials. Because stainless does not have a reaction to any material when used, so it does not affect food or others.

10. Resistant to corrosion

The main advantage of stainless steel is anti-corrosion. Because that is what makes stainless kitchen equipment a top choice for restaurants, restaurants, hotels, and other kitchens.

11. Available in various tools

Because stainless steel has many advantages, so that almost all kitchen equipment are using stainless steel as its material.

How to Use & Care Stainless Steel Cookware

Avoid using steel wool (metal dishwashing foam / wool) to avoid scratches. If you must use a metal spatula, use it slowly so as not to scratch the surface of the stainless steel. Scratches on the surface of stainless steel will be difficult to remove.

Do not heat stainless steel in an empty condition because it will cause smoke and color marks that arise will be difficult to remove.

After use, wash with soap thoroughly, dry with a cloth so as not to cause water stains. As long as maintenance is correct, stainless steel cookware will remain durable and long-lasting.

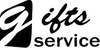

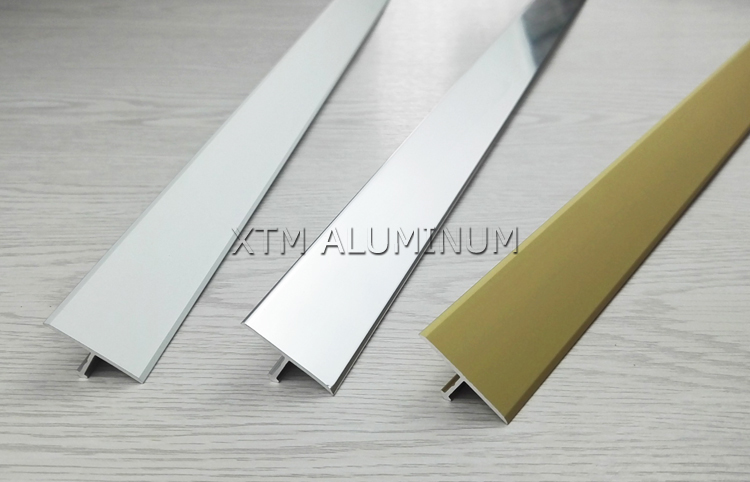

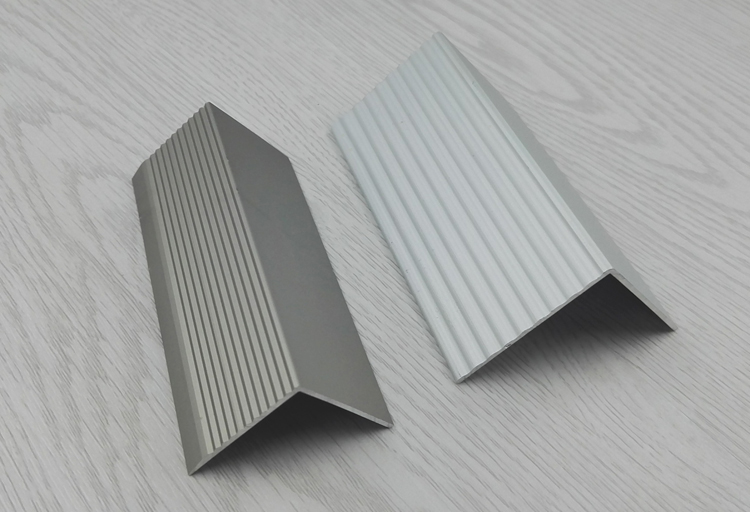

Our Partner

As we are cooperating with a huge aluminum producer who has 350 workers and staff, as well as 8 extrusion lines ranging from 600 tons to 1000 tons. We are ready to provide you any kind of metal custom production. Which not only suitable for a gastronomy industry used such as catering, restaurant or tavern, but also for furniture, tile trims, floor trims, machines, etc.

dav dav dav dav

Trim itself is a decorative ornament that is often placing on the roof, windows, doors or ceiling of the house to make it look more beautiful. Not only for decorative functions, it turns out that the trim also provides a functional aspect to your home. It gives a dynamic aspect to home exteriors, create a clear partition to home interior and also to protect the windows from the rain leakage. So, do not hesitate to have your offices’ or houses’ trim customized.

dav dav dav dav

Are you interested in having any metal-based customized products? Or having any questions regarding the products you need? Please reach us by email at: info@predmetyreklamni.eu

Please state the necessary information for the product such as: types of products, quantity, and material used. All this information will help us to individually customize the offer just for you.

We are looking forward to collaborating with you! Team Gifts Service

References: