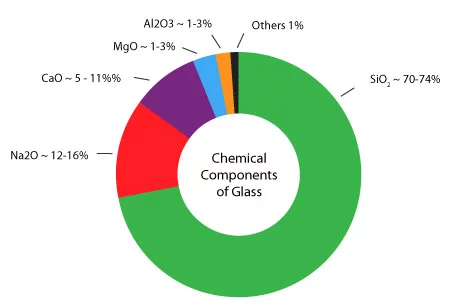

The main component of glass is silica sand which must be fine grained and clean and constitutes about 70% of the raw materials required for glass manufacturing. During the glass making process soda is added to silica to reduce the extremely high melting temperature of silica. Along with the calcium carbonate is added to make it more stable and consistent. The glass is etched with a colour by using different ions.

There are hundreds of different compositions of glass, depending on what are the final use and what are the properties desired. The majority of glass is made in two different methods, the first one is the float process method such s window glass and windshields and sidelights and the second one is containers.

The main ingredients or components of glass

- Sand or Silica or Silicon dioxide is the major component making up to 70% or more of the ‘batch’.

2. Calcium carbonate (aragonite, seashells), Sodium carbonate (soda ash), Potassium carbonate (potash), and barium carbonate or sulfate (barytes) are the next major components and are known as modifiers.

Sodium carbonate (soda ash),

Potassium carbonate (potash)

barium carbonate or sulphate (barytes)

- Sodium sulphate, Arsenic oxide, antimony oxide, tin oxide (rutile), and sodium chloride are added as fining agents to help reduce the bubble size and aid in the reabsorption of the gases into the glass matrix. One or more are generally used at a time. They will also help impart other qualities into the glass, such as lustre and brilliance.

- Iron, cobalt, manganese, and chromium generally in the form of oxides are introduced into the glass as colorants. Other mineral compounds are also used, and all of these will be added either singularly or in combination in trace amounts (relative to the size of the batch) to impart a specific colour or other specific property.

Sources: http://www.lehigh.edu/imi/teched/GlassProcess/Lectures/Lecture02_Hubert_Melting%20and%20fining%20processes.pdf