3D printing is easily the most popular choice for prototyping in Australia today—and it’s not hard to see why. Whether it’s 3D printing with rubber, silicone, or metal, the biggest advantage is the ability to quickly develop products and make design tweaks in no time flat. This flexibility allows for rapid testing and perfecting of prototypes. With 3D printing in rubber, silicone, and metal, you can swiftly adapt to changes in design, functionality, or user preferences, making it an unbeatable tool for Aussie businesses looking to stay ahead of the curve.

We are able to produce anything you can think of for you. This can include prototyping in rubber, silicone, steel, metal and other alloys. Feel free to contact us to facilitate your product development.

3D printing from rubber and silicone – the advantages

We offer a huge range of possibilities to Aussie businesses! 3D printing with silicone and rubber is versatile enough to cater to just about any industry. Whether you’re in manufacturing, healthcare, or product design, you can reach out to us for virtually anything. With years of hands-on experience and a track record of successful projects, we’re equipped to handle any challenge with ease. Let us help you streamline and speed up the development and production of your products. And don’t forget—with 3D printing in silicone and rubber, your customer’s specific needs can be seamlessly incorporated into the design process, giving you the flexibility to deliver exactly what’s required. Let’s make your ideas a reality!

Printing from elastic materials

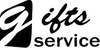

Printing from elastic materials is widely used in prototyping. The great advantage is that printing can be arranged for small batch production at very reasonable prices. This production is very popular in the production of soles for footwear.

- 3D printing from rubber, silicone and metal – offer

- production of custom accessories in rubber, silicone, steel, metal or alloys

- custom made sealing sleeves

- custom rubber/metal components

- decorative design and functional elements

- weapons, special tooling and silicone components

- manufacture of covers and packaging according to drawings

- Dielectric, professional, anti-slip and medical sterilizable silicone pads

- rubber soles

- and many more

- Also:

- promotional items

- bracelets, pendants

- wallets, cases

- kitchen utensils

- custom manufacturing of industrial silicone parts and components

- watch straps

- silicone caps

- silicone bottles, cups

- and many more

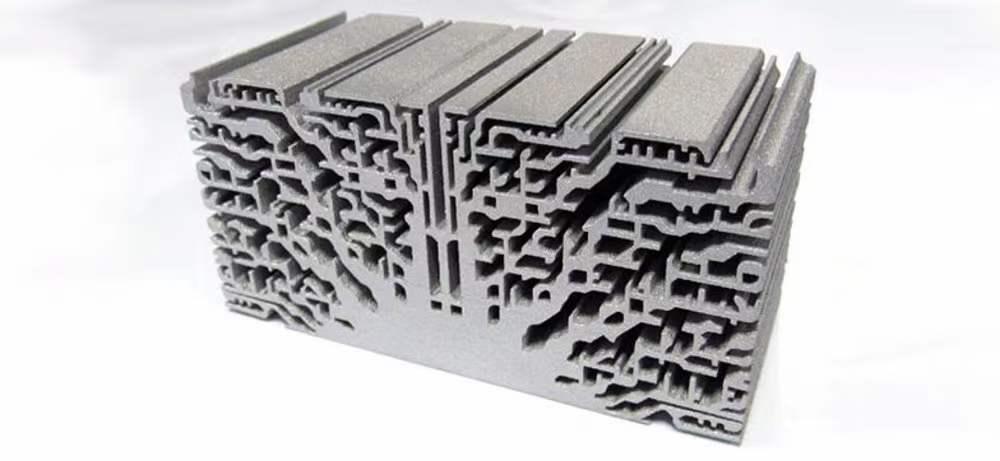

The production we have at our disposal is equipped with all modern production technologies. 3D printing in metal and steel will save you time and money. Production is possible from small batches, giving you the ability to change designs quickly or react to customer requirements in a flash. Steel and metal prototyping is a very popular and used option nowadays. Speed and low cost are the clear advantages of metal and steel printing.

3D printing from alloys

An alloy is a mixture of a metal with other metals, elements or compounds, usually in the form of a solid solution. It is a very widespread and diverse industry. We can custom make anything to your exact specifications.

Contact – 3D printing in rubber, silicone and metal

Do not hesitate to contact us and have components for your production made cheaply and reliably. It will give you the opportunity for fast development of your products and possible superior lightning response to customer needs.

Contact us by e-mail:

sales@giftsservice.com